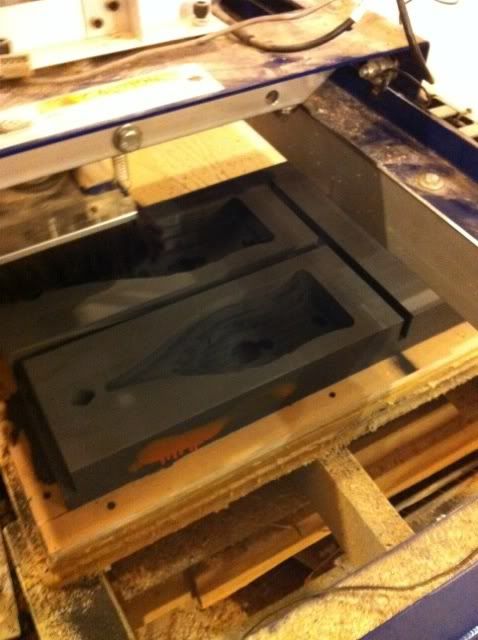

this was a rush job (nothing new there) that I was only told about on the way to work. well my customer buys this big block of solid graphite. it was about 24"x13"3/5" thick. one face and two edges were flat and straight. the top looked like a lava flow. I wish I remembered to take a picture. but I was stressing on this as the material was 1500.00 the stress of cutting this was pretty high. likely I had cut this before in wood so I just used the same settings. I just used wood blocks around it to keep it in place. weight kept it down. I had to shave of 1/2" to get it flat. nothing like 100.00 or so of dust in my dc. I bet 400 or so of dust wasted. well anyway I just have pics of the roughing and finished. I roughed with a 1/2" bit and finished with a 1/4" ballnose and 4% stepover. these are 12" long bottles and they are just a mold for the first test bottle.

Reply With Quote

Reply With Quote