his was my quest to get a quiet vac setup to replace my two melted fein vac setup. By themselves the fein motor is almost 100 decibels it is a real screamer for sure. but You stick it in a simple baffled housing and and it is 76dbs and you have a 450.00 fein vacuum. depending on what motors you use you can make this setup for less then one fein.

for this setup I used two of these http://www.grainger.com/Grainger/AME...um-Motor-2M433 but I am going to hunt for the exact fein motor and check the prices. these do drop into a fein vacuum though and are about as big as they make them.

This design only works for this type of motor. it will work for others but it will not muffle them to my disappointment. I am not sure why as most of the noise is the screaming fan on top.

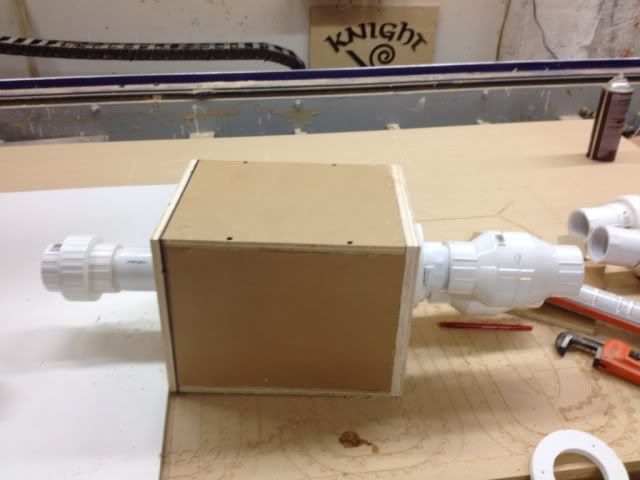

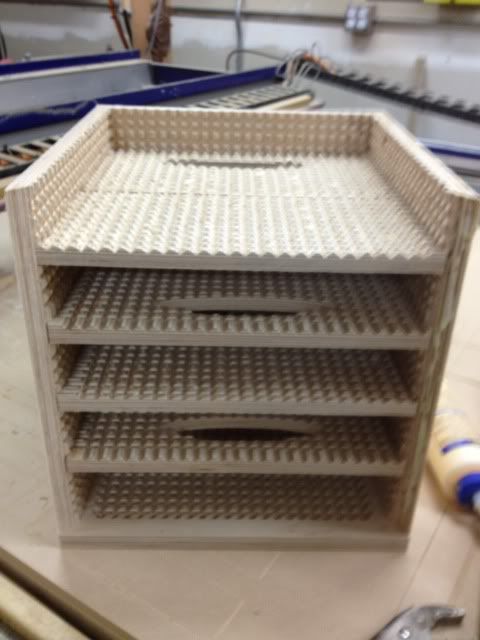

measurements are not critical for this setup. The box the motors are in is sealed on the bottom for the vacuum ( I have a separate filter box because I have two vac boxes) so you want to make the box large enough to fit a shopvac cartridge filter in.

I use 3/4" plywood for the box as it is airtight and strong but mdf will work as long as you seal the insides of the box (I use yellow glue) I use a hole in the side for a pvc coupler fitting. the platform the motors sit on have two holes for the motor. the size is not critical as the hole in the bottom of the motor is only about 1.25" Then a hole in the box the same size as the bottom one for the blower air output. I will be putting a muffler on mine to see how much it reduces noise. the one critical measurement is to have the top of the box either be about 1/8" to 1/4" below the top of the motors or if you want to use thick neoprene as a seal on the bottom of the lid slightly above the motors. even if the top is a bit high you can make rings to bring it down to the right level.

Reply With Quote

Reply With Quote