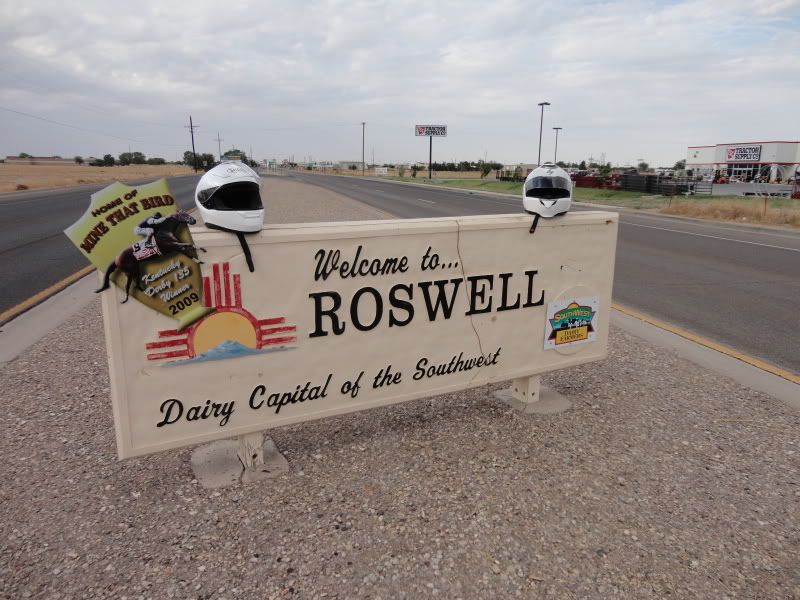

We did a U turn when I saw this one.

Don't you know the sign company who sold this sign told the City of Roswell they were getting a fool proof material that will last for years!

This sign was 4"X4'X10' and what do you know it's CRACKED. Most of us using these materials have found the best way to use them. We've glued aluminum, angle iron, and MDO in HDU trying to overcome it's weaknesses.

I've come full circle by returning to wood as the major substrate for all my signs. The only time I use HDU is for detail carving on logo's and lettering.

The helmets aren't part of the sign.

Joe Crumley

Reply With Quote

Reply With Quote

[/IMG]

[/IMG]