It's funny how fast time just flies by...I wanted to do this about 4 years ago, but am just getting around to doing it now. In the last week or so I essentially did a case study on pineapple models for various applications. It is amazing how much leeway there is in our collective agreement of what we perceive as being a 'pineapple'! Some are just criss-cross patterns, others have 4, 5 or 6-sided polygon textures, and some are not even really pineapples at all, but artichokes or some other strange permutation. It was an interesting study. It would have been easy to just buy an existing model, but I wanted my own original model, with no strings or copyrights to worry about.

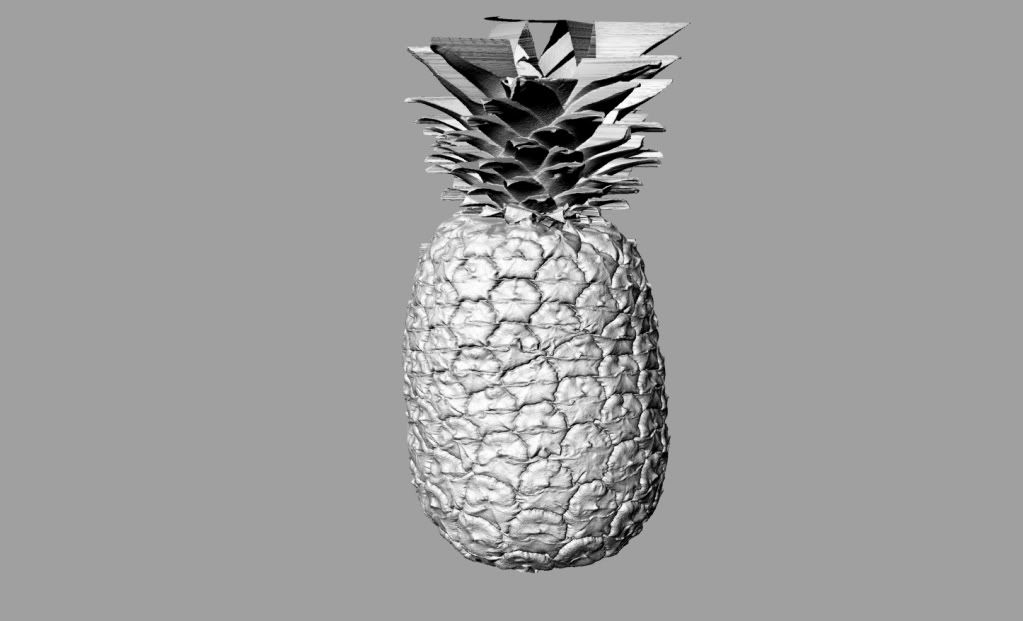

Yesterday I went to the food store to peruse the produce section. I spent a good solid 5 min rooting through the pineapples to 'find a good one'. On sale no less for $2.99! I finally settled on one, and then prepped it for scanning. I shaved off all the spikes on the body of the fruit so that they didn't wind up being the dominant texture. I also trimmed off some of the top leaves - which are ALWAYS a problem since they don't really have much thickness to them and they create a lot of undercuts, as you can see in the screenshot of the data. It's kind of a moot point because 4th axis machining doesn't let you get to undercuts like a 5 axis machine could. It's really no different than 3 axis machining in this regard.

I've scanned a lot of natural 'models' over the years, and what's funny is, in nature, there is no such thing as 'perfect' as it relates to symmetry and the ideal layout, shape or config for woodworking. I'm sure Fibonacci would prove this wrong, but in my experience, the only 'perfect' pineapples I've ever seen were fake! Such is life when dealing with natural materials and models.

I had some teak glue-ups sitting around from another job and rather than wait for a full-scale size glue-up to dry I decided to jump in and machine this. It was pretty dense stuff so I was conservative with speeds and stepdowns. The original is about 11 inches or so tall and this one worked out to be around 7"+ in length. I scaled it down to match the 3.875" glue-ups. The leaves were machined down to an 1/8" ball because a 1/16 would have never made it that deep. I lost a pretty decent number of leaf tips while machining, but I was expecting that. The body/bulb itself was machined with a 1/16" ball to capture all that fine detail, although it could have used a 1/32" ball to really get it all...but I want to go to bed some time this century!

Here's a shot of the original and the scaled down one. I tried to clock them in the same position for comparison:

I'm not a good photographer - as you can see! But here's another with the carved one in the palm of my hand:

It really came out well. I tried taking a few pics of it right off the machine, but it didn't show up well. I slapped on 2 coats of shellac in about 15 minutes and buffed the body with a scotch pad in between. This made it a lot easier to see the detail. At some point I'll probably dumb down the leaves to make machining cleaner and faster.

This was a good test for some new indexer hardware I am running. I've got a few more rotary models that I scanned and will be machining soon...so stay tuned.

-B

Reply With Quote

Reply With Quote