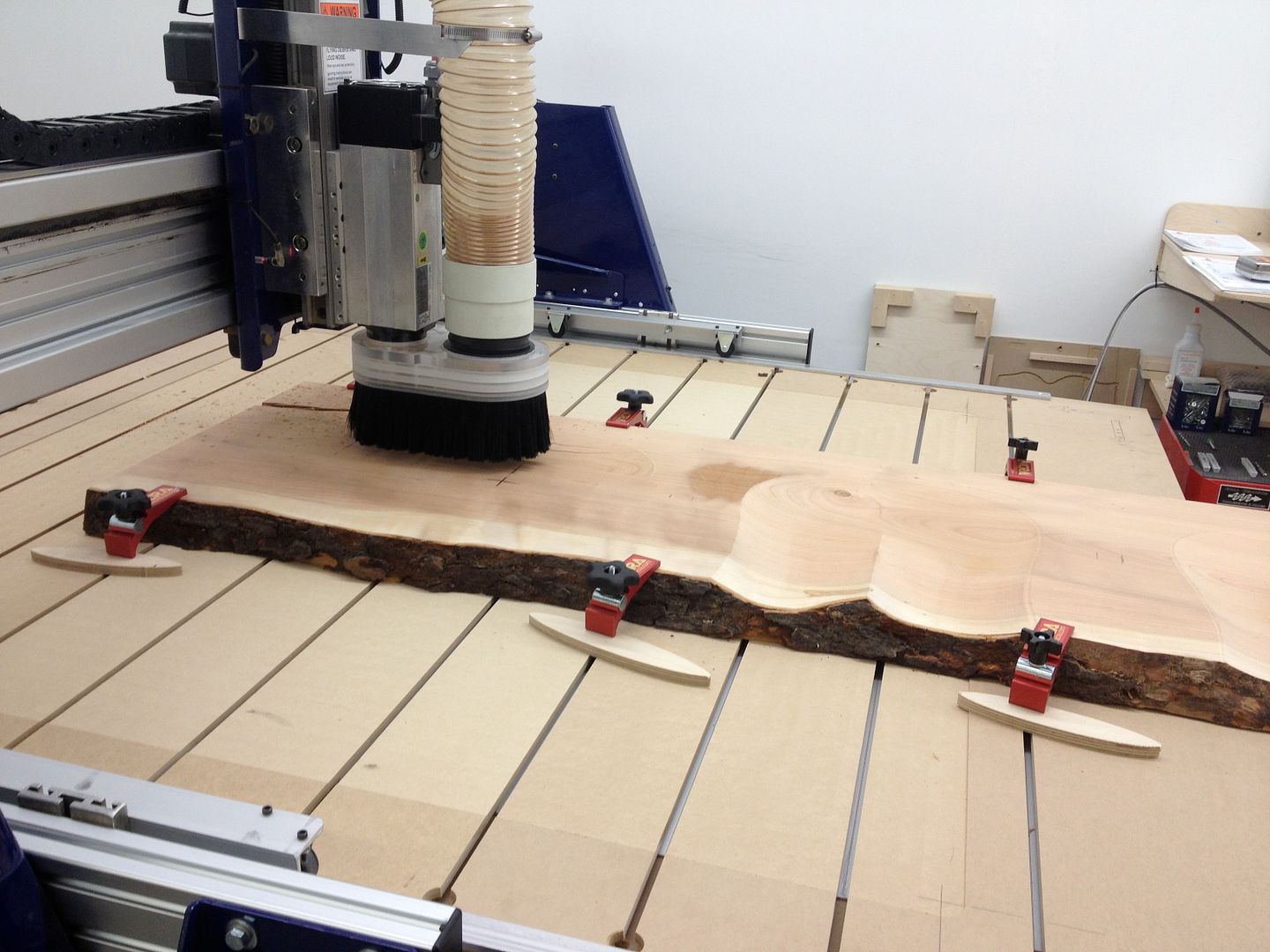

I outfitted my table with both traditional (wood) and T-slot extrusions. I have it split with a 96x48 section of wooden table with a vacuum plenum and 13.5" of clamp area using the T-Slot material. I use 4.5" x 1.5" (series 15) extruded aluminum from 80/20.

The extrusions I use are slightly smaller than SB's standard side components (6" x 1.5" vs. 4.5" x 1.5") but the same T bolts fit.

A standard 5/16" carriage bolt works great in the series 15 style extrusion.

Here's a picture of my setup:

ShopBot Details:

2013 PRS 96x60x12 (Centroid upgrade)

4hp Spindle

12" indexer

Aspire

Rhino

Fusion 360

Ferrari 360

Prusa MK3S+

Prusa XL multi-tool

Reply With Quote

Reply With Quote