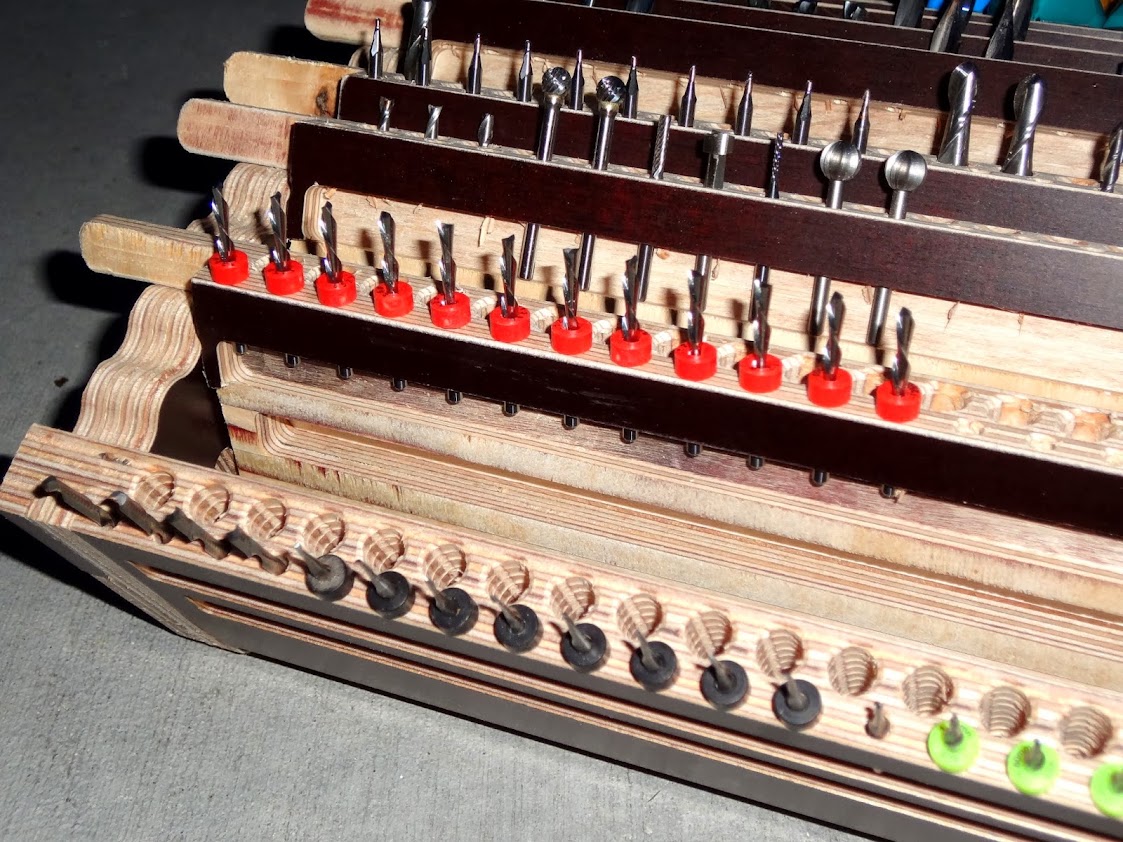

Since I started working with CNC machines some 4 years ago I purchased various bits, sometimes in bulk for smaller sizes that I like to use. I made a tray with holes to hold them but that was soon overflowing and I ended up with router bits everywhere, not knowing what was still there and sometime buying stuff again that I still had in a drawer somewhere.

So, today I made a high density bit organizer that can hold all the bits that I have. Theoretically up to 400 but practically maybe half of that. I still have to mark the ones that are in use right now (or vice verse the ones that are just inventory), maybe with a piece of tape. I think it will do the job. The moving "ammo clips" allow presenting the type of bit I need.

Reply With Quote

Reply With Quote