I am working on another piece of custom CAM software. I have not forgotten about finishing the Maze software but I dug out a (currently more fascinating) old project to create tool paths for flat machined void free finger/box joints.

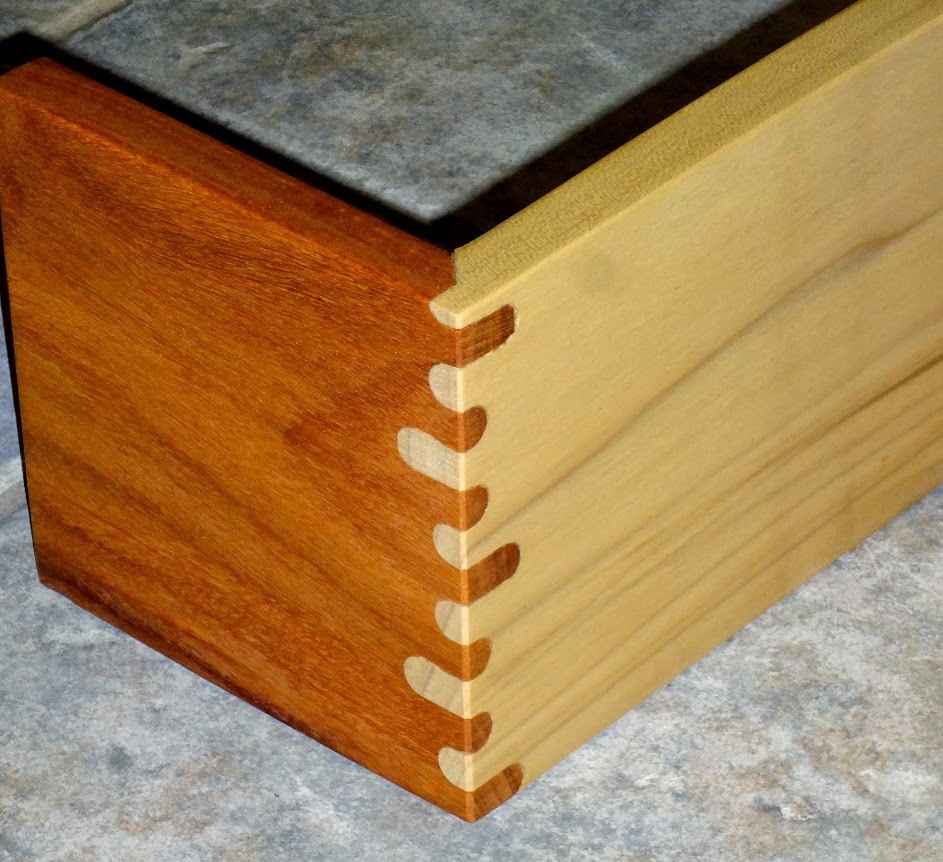

While I use my dovetail software occasionally, most of my project joints are just cut as plain box joints for simplicity and because I can cut the whole part out of a sheet or board without re-clamping. However, it bothered me that such simple box joints need dogbone fillets for the inner corners to avoid interference with the sharp cut edges.

The whole idea is to cut the joints with a ball end mill and to allow for some decorative patterns using varying finger lengths, either two sided or half blind. The pattern generation was not too bad but I gave up last year over the calculation of the tool paths. Anyway, after a few sleepless nights I finally figured out how to do it. Getting all the bugs out will take a lot more work but today I made my first successful joint.

Reply With Quote

Reply With Quote