Well, the UPS man just dropped off my box of Festool 50mm vacuum hose.

I certainly hope that the hose will withstand the vac, it is much more substantial than the shopvac hose.

I will cut the hose and install it tomorrow, and give it a test run!

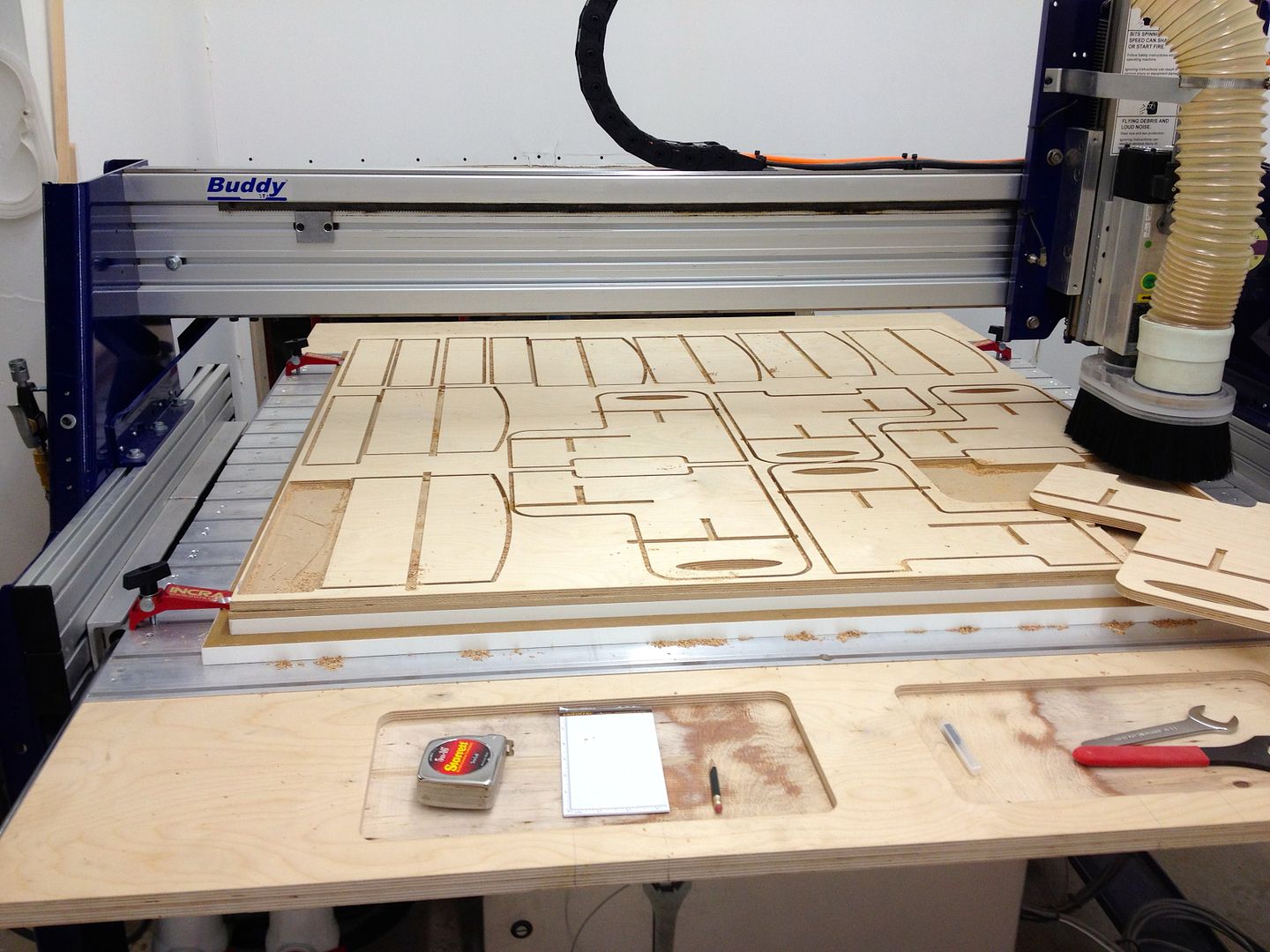

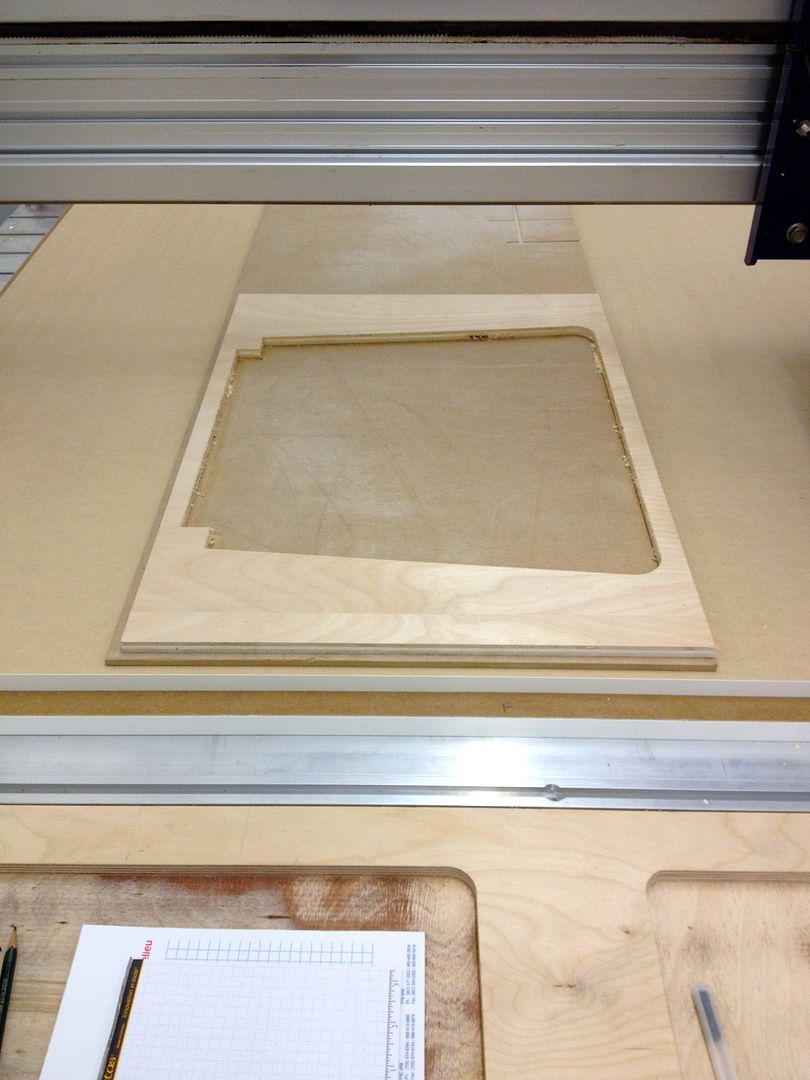

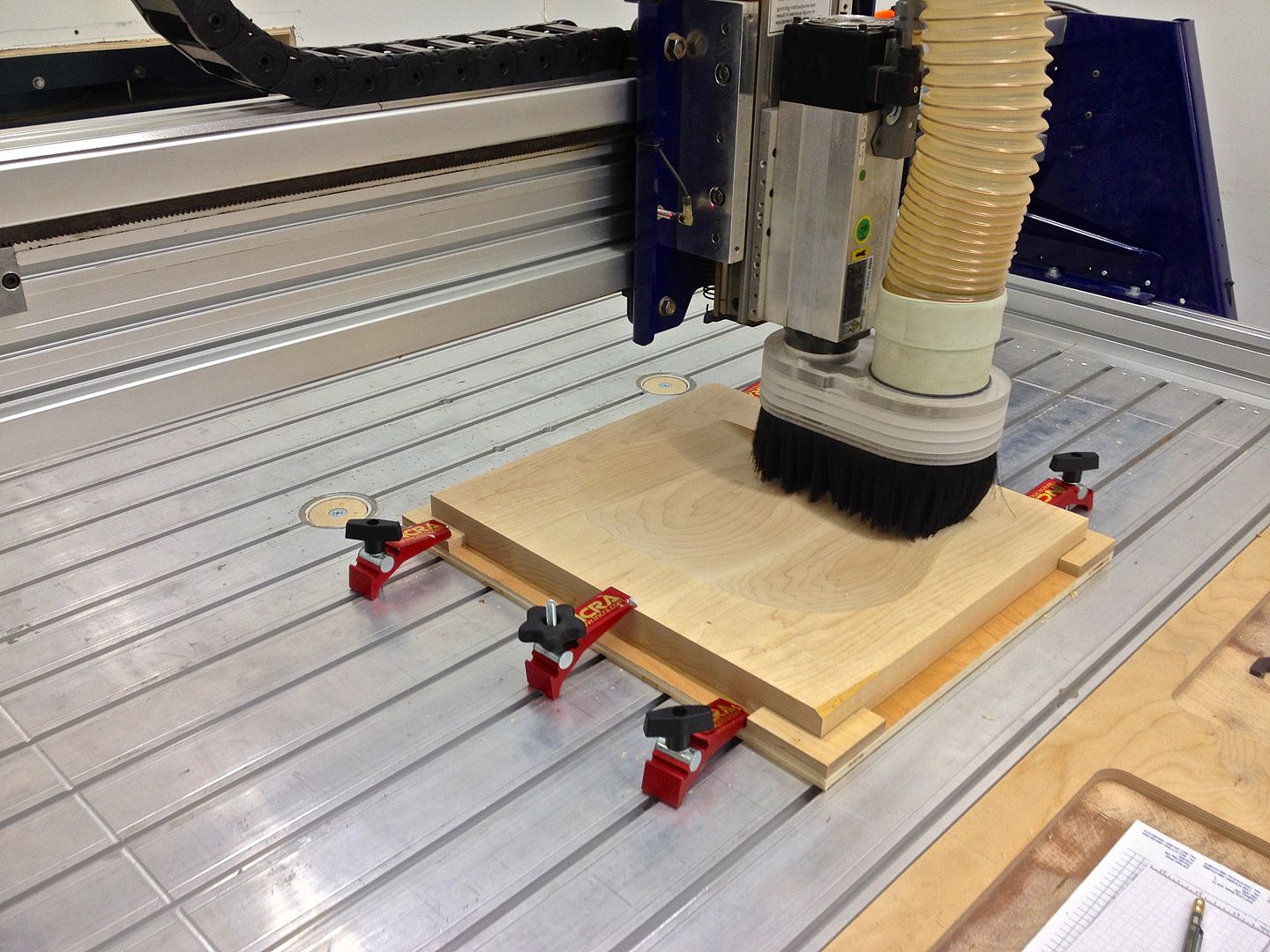

I already have a test file to cut - a 1/2 sheet of 12mm Baltic birch, that I cut out three sets of parts for one of my children's step stools. But this time no tabs

More feedback tomorrow! If it works, I can call the installation a success and finished. If it doesn't, well not sure what the next step is in terms of hose... but I'm going to be positive and figure the German's know how to make a decent vacuum hose

Reply With Quote

Reply With Quote