So, in January 2012, just before I bought my SHopbot router (took delivery mid February 2012) I built a Maloof rocker out of walnut. I built it for myself, but had it displayed at a local trade show and I was made an offer, so I sold it.

Ever since I bought my Buddy BT48 Alpha, I have been busy making chairs (one of the main reasons I bought a CNC router). I have also wanted to build another rocker... for myself.

I recently got my hands on some very nice 8/4 figured maple. I decided to get another rocker done before the end of April - you got it, for the next home & trade show.

The first step was to rough cut the seat shape, and carve the saddle shape. The "old school" way (with shaves and chisels) took me 6 hours to hand carve a seat - using templates and other measurement tools to keep everything symmetrical.

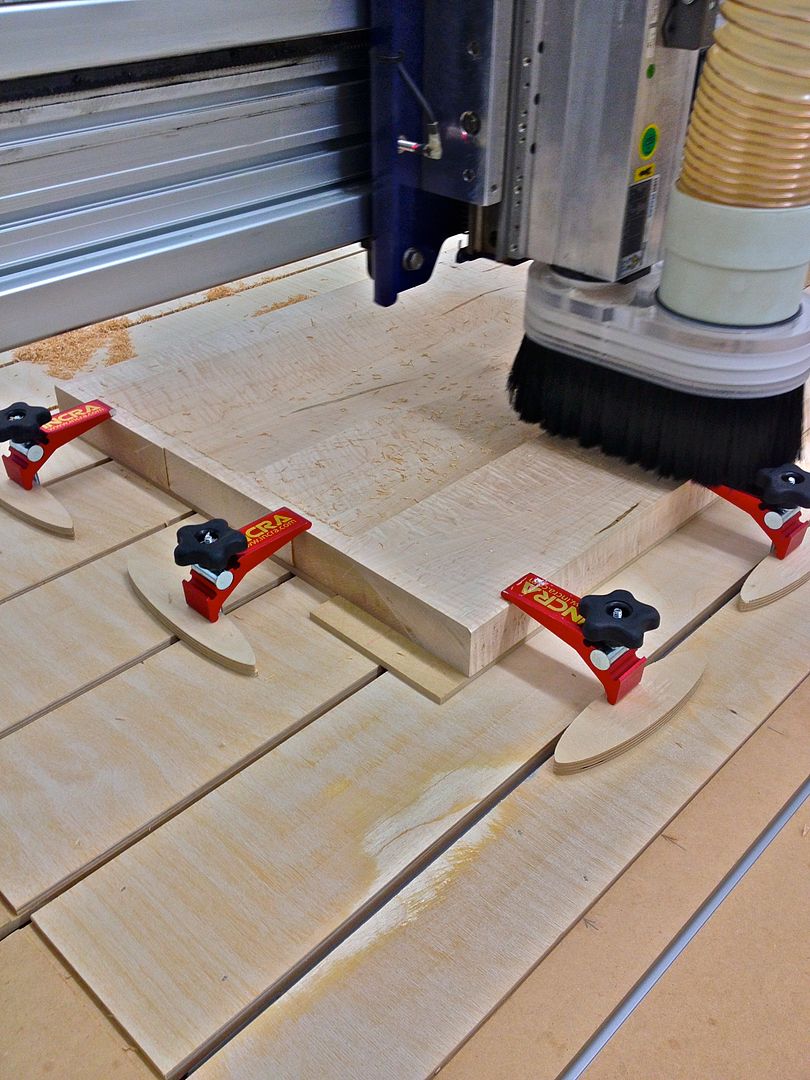

Today, it tool me between 10 and 15 minutes in Aspire to draw up the seat, create the cut file - and 47 minutes to cut it out. I used my trusty Onsrud 5/8" solid carbide ball end spiral, 10,000 rpm - 3% stepover and 400 ipm feed. With just a hair over 1/64" stepover, there is almost no machine marks left to sand out. Sweet! And it is perfectly symmetrical. This is too easy...

The legs and crest rail I have rough cut the material for - I plan to use the CNC for more shaping on some of the parts. Will post more as I get to it - in between other jobs. Currently I have two medium sized custom wood kitchens, some interior doors, 3 mantles, & a dining table on the go (at the same time!)

But if I take 1/2 hour here and there, over the course of several weeks I'll get it done.

Reply With Quote

Reply With Quote